Always by Your Side

We are more than just a supplier—we are your trusted partner. Through fast and effective consulting and after-sales support, we find the ideal design and production solution for every need. We offer a wide range of panels and pre-processing services, including cutting, edging, CNC machining, drilling, and panel lamination. Every stage, from material arrival to final delivery, undergoes strict quality controls to ensure flawless products. Thanks to our logistics facilities, we manage customized warehouses for clients and ensure timely, reliable deliveries with our own fleet.

READY STOCK

Fast and punctual deliveries to keep you competitive. ICAM has invested in a fleet of vehicles to bring panels wherever you need them. Partial deliveries within 5 working days within 100 km, while full loads arrive within 2 days (whole goods) or 5 days (cut goods) within a 300-400 km radius.

JUST IN TIME

Speed and adaptability at your service. ICAM ensures fast deliveries for every type of panel. With an in-house warehouse of 2,500 m³, we always have a wide selection of wood products available. For specific needs, we can reserve dedicated storage spaces for custom products, directly accessible to our clients. With an advanced order management system and state-of-the-art machinery, we minimize processing times without compromising quality.

NESTING

In the world of woodworking, Nesting is an innovative solution for optimizing panel cutting, ensuring maximum efficiency and minimal waste. Compared to traditional panel saws, it offers significant advantages, especially for materials like chipboard, MDF, and solid wood.

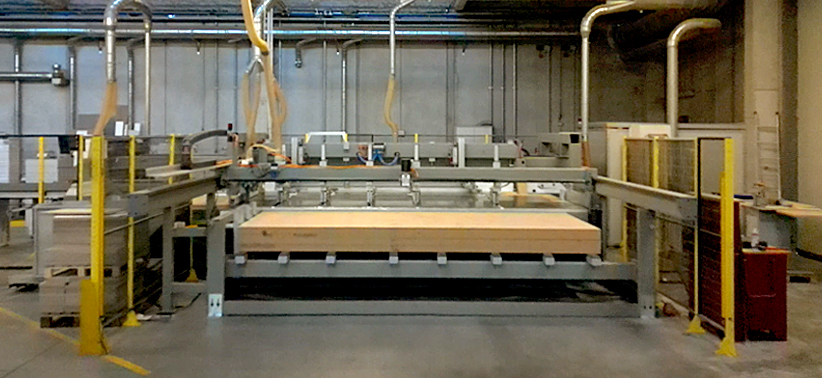

PANEL CUTTING

Custom Cuts, Precision, and Efficiency Using advanced machinery, ICAM performs customized panel processing for all sizes, optimizing time, costs, and reducing waste. The result? Cost-effective, tailored solutions for you.

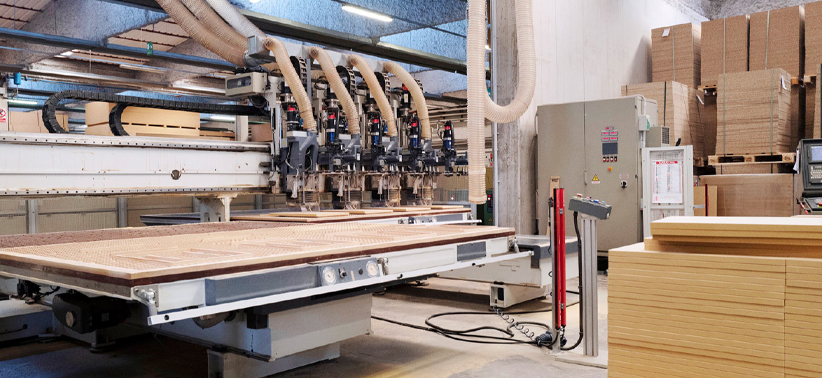

PANTOGRAPHING

Precision and Custom CNC Processing From engraving to milling, drilling, and shaping, ICAM executes each project with precision and attention to detail. Thanks to CNC machines and a specialized team, we ensure high-quality results and endless customization possibilities.

CONTRACT MANUFACTURING

Precision and Custom CNC Processing From engraving to milling, drilling, and shaping, ICAM executes each project with precision and attention to detail. Thanks to CNC machines and a specialized team, we ensure high-quality results and endless customization possibilities.